TRI’s Capabilities and Accreditations

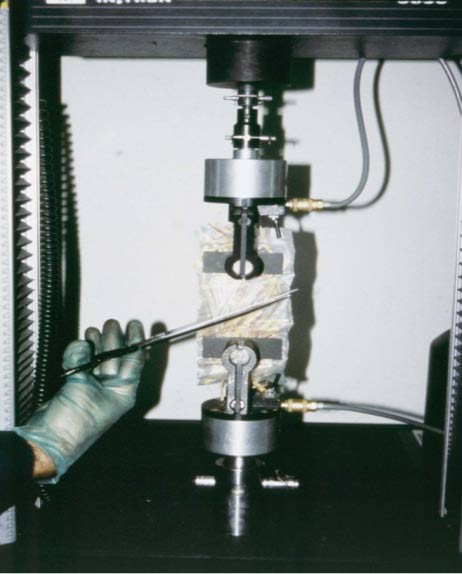

TRI is unequaled in implementing test methods

to assist clients with product characterization.

TRI/Environmental, Inc. (TRI) is an independent, third party, testing firm providing testing and research services to the international community. TRI is unaffiliated with any manufacturer or engineering firm, and thus provides impartial/unbiased services to regulators, manufacturers, engineering firms, contractors and installers.

TRI provides laboratory conformance/verification testing as well as performance related studies. In addition to routine index testing in accordance with ASTM, ISO, BS, DIN and GRI test methods, TRI also provides bench scale indicator tests, and large scale performance test procedures.

TRI Erosion Test

Materials tested include:

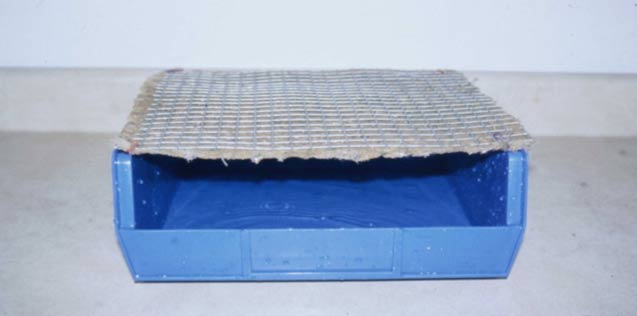

- Rolled Erosion Control Products (RECP)

- Erosion Control Blankets (ECB)

- Turf Reinforcement Mats (TRM)

- Hydraulically Applied Erosion Control Products (HECP)

- Sediment Retention Fiber Roll (SRFR)

- Erosion Control Mulches

- Waddles

- Compost Logs

- Anchoring Systems

- Membrane barriers

- Geotextiles

- Plastic Pipe

- Roofing and Green Roofing Material

TRI’s state-of-the-art large-scale facilities at Denver Downs Research Facility (DDRF) make it the only independent commercial laboratory offering such a wide array of performance testing capabilities.

HISTORY:

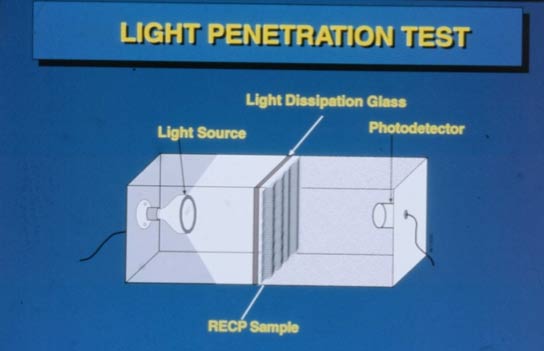

In 1994, the Erosion Control Technology Council (ECTC), an organization of rolled erosion control product (RECP), hydraulically applied erosion control product (HECP), and sediment retention fiber roll (SRFR) manufacturers commissioned TRI/Environmental to initiate a program to identify and establish a common terminology and to develop standardized index tests for the characterization of RECPs. This was only the start. Subsequent test development of bench-scale and large-scale performance tests has positioned TRI as a world-wide leader in erosion control product (ECP) and sediment retention device (SRD) characterization.

Many of these development efforts, have been coordinated through the ASTM International development process to achieve consensus standardization of test procedures.

In the tabs ABOVE you will find information on our performance test methods for our Index Tests, Bench Scale Tests, and Large-Scale Tests

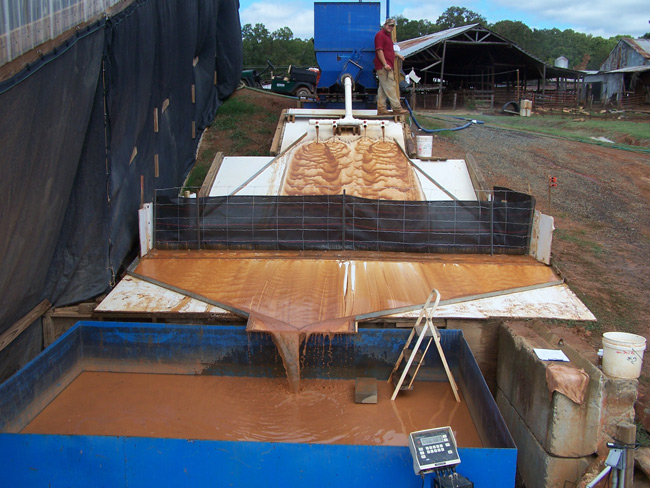

Large-Scale Performance Testing

TRI’s large-scale erosion and sediment control testing facility in the upstate of South Carolina at the Denver Downs Research Facility (DDRF) expands on our industry-leading index and bench-scale erosion and sediment control testing capabilities.

- ASTM D 6459: Determination of Rolled Erosion Control Product (RECP) Performance in Protecting Hillslopes from Rainfall-Induced Erosion;

- ASTM D 6460: Determination of Rolled Erosion Control Product (RECP) Performance in Protecting Earthen Channels from Stormwater-Induced Erosion;

- ASTM D 7208: Determination Of Temporary Ditch Check Performance In Protecting Earthen Channels

- ASTM D 7351: Determination Of Sediment Retention Device Effectiveness In Sheet Flow Applications

- Additional Non-Standard Large-Scale Tests

ASTM D 6459:

Determination of Rolled Erosion Control Product (RECP) Performance in Protecting Hillslopes from Rainfall-Induced Erosion.

This is full-scale simulated rainfall on 3:1 slopes with bare and RECP-protected soil, including:

- Rainfall Intensities = 50, 100, 150 mm/hr @ 20 minutes each;

- 1 control + 3 replicate slopes;

- Inclined (3:1) slopes, 40-ft long and 8-ft wide;

- 12-inch compacted soil veneer;

- Simulated rain system with 14-ft drop height & up to 6+ inches/hr capacity.

ASTM D 6460:

Determination of Rolled Erosion Control Product (RECP) Performance in Protecting Earthen Channels from Stormwater-Induced Erosion.

This is full-scale channel flow with RECP-protected soil, including:

- Increasing Shear Levels psf @ 30 minutes each;

- 3 replicate test sections;

- Rectangular (flume) or Trapezoidal cross-section;

- Rectangular cross-section has 2-ft width and 2-ft high side walls and either 10% (unvegetated) or 20% (vegetated) bottom slope.

- Trapezoidal cross-section has 2-ft bottom and 2H:1V side-slopes and a 5% bottom slope;

- 12-inch compacted soil veneer;

- 40-ft total length;

- Flow capacity up to 50cfs for 30 minutes in rectangular flumes.

- Flow capacity up to 20 cfs for 30 minutes for trapezoidal channel

ASTM D 7208:

Determination Of Temporary Ditch Check Performance In Protecting Earthen Channels

This is full-scale channel flow (up to 3 cfs) in a trapezoidal channel with check structure(s) installed. The test method evaluates the ability of temporary ditch checks to protect earthen channels from storm water-induced erosion. Critical elements of this protection are the ability of the temporary ditch check to:

- Slow and/or pond runoff to encourage sedimentation, thereby reducing soil particle transport downstream;

- Trap soil particles upstream of structure; and

- Decrease soil erosion.

This test method utilizes full-scale testing procedures and is patterned after conditions typically found on construction sites at the conclusion of earthwork operations, but prior to the start of revegetation work. Therefore this test method considers only unvegetated conditions and provides a comparative evaluation of a temporary ditch check to baseline bare soil conditions under controlled and documented conditions.

ASTM D 7351:

Determination Of Sediment Retention Device Effectiveness In Sheet Flow Applications

This is a full-scale installation of an SRD in which sediment-laden water is allowed to “sheet flow” up to and seep through, over, and/or under an installed sediment retention device (SRD). The measurement of sediment that passes through, over, and/or under the SRD compared to the amount in the upstream flow is used to quantify the effectiveness of the SRD in retaining sediments.

An important variable in any testing procedure is the establishment of test “conditions”. For a sediment control performance test this means selecting an appropriate design storm event and associated runoff along with an expected amount of sediment to be transported by the runoff. The default for D 7351 is a standard 10-year, 6-hour storm event (mid-Atlantic region of US). This return frequency is commonly used for sizing sediment control ponds and, thus, was deemed appropriate for the testing of other SRDs. Using this criterion, a 100 mm (4 in) rainfall was selected. It was also assumed that approximately 25% of the storm would occur during the peak 30 minutes, and that 50% of the rainfall would infiltrate into the ground. A theoretical contributory area of 30 m (100 ft) slope length by 6 m (20 ft) wide was selected to limit runoff to sheet flow conditionsRunoff and associated sediment were calculated using the Modified Universal Soil Loss Equation (MUSLE) which allows for calculating a storm-specific quantity of sediment.

Additional Non-Standard Large-Scale tests:

The following non-standard large-scale tests are also available to assist clients with product development and characterization:

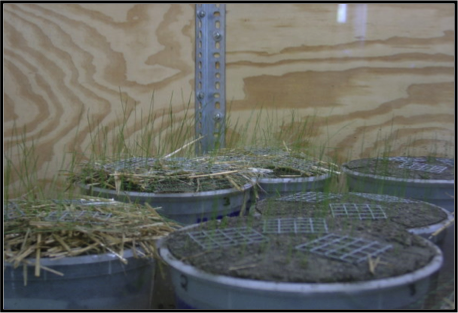

- Vegetated RECP shear testing in 20% channels in accordance with ASTM D 6460;

- SRD effectiveness in inlet flow applications (D7351-modified);

- Storm water inlet protection provided by sediment retention devices in curb and gutter applications;

- SRD effectiveness in construction perimeter control applications (TM11340);

- Pond skimmer evaluations and flow capacities;

- Shoreline protection under wind-induced wave action ;

- Buried pipe and stormwater chamber strength/durability evaluations;

- Large-scale germination and functional longevity testing of erosion control products.

Erosion and Sediment Test Labs

Index Tests &

Bench-Scale Performance Tests

TRI’s laboratories are the leading commercial laboratories for index and bench-scale testing of Erosion Control Products and Sediment Retention Devices. TRI has been conducting tests on ECPs and SRDs for over 20 years.

Currently, all index and bench-scale testing on ECPs for the National Transportation Product Evaluation Program (NTPEP) is performed at TRI’s laboratory. The results of all NTPEP testing are posted at www.ntpep.org.

Additionally, product development and annual quality assurance testing is done for numerous ECP and SRD manufacturers.

The lab locations are:

Index test turnaround time:

Bench-scale performance test turnaround time:

Large-Scale

Performance Tests

TRI’s Denver Downs Research Facility (DDRF) in Anderson, SC, is the lead commercial laboratory for large-scale testing of ECP and SRDs.

TRI began operations at DDRF in 2007 and has, since that time, performed independent large-scale performance tests on a wide range of ECPs and SRDs. Since the Fall of 2009, TRI’s DDRF has been the contract lab for the NTPEP’s large-scale ECP slope and channel erosion testing and added large-scale SRD testing in the spring of 2016.

The results of all NTPEP large-scale testing are posted at www.ntpep.org.

In addition to NTPEP, TRI has performed testing for WisDOT, SCDOT, the Georgia Soil and Water Conservation Commission and several dozen private companies.

The lab location is:

Large-scale performance test turnaround time:

TRI Erosion Test is trusted by:

Find us.

Denver Downs Research Facility

4915 Hwy 76 (Clemson Blvd.)

Anderson, SC 29621

Call us.

864.569.6888